Core Concept and Operating Principles

At a fundamental level, a Cylindrical capacitor stores electrical energy in an electric field formed between conductive electrodes separated by a dielectric material. When integrated into AC power systems, Capacitors are primarily used to compensate for inductive loads, improve power factor, reduce line losses, and stabilize voltage.

The cylindrical form factor is not merely a packaging choice. Compared with rectangular or box-type designs, cylindrical capacitors offer more uniform mechanical stress distribution and predictable heat dissipation paths. This geometry supports higher operational stability under continuous load, especially in environments with elevated ambient temperatures or frequent load fluctuations.

In power compensation systems, these capacitors are typically connected in parallel with inductive equipment, supplying reactive power locally and reducing the burden on upstream power infrastructure.

Product Structure, Materials, and Manufacturing Processes

A typical cylindrical capacitor consists of several key structural elements, each influencing performance and service life.

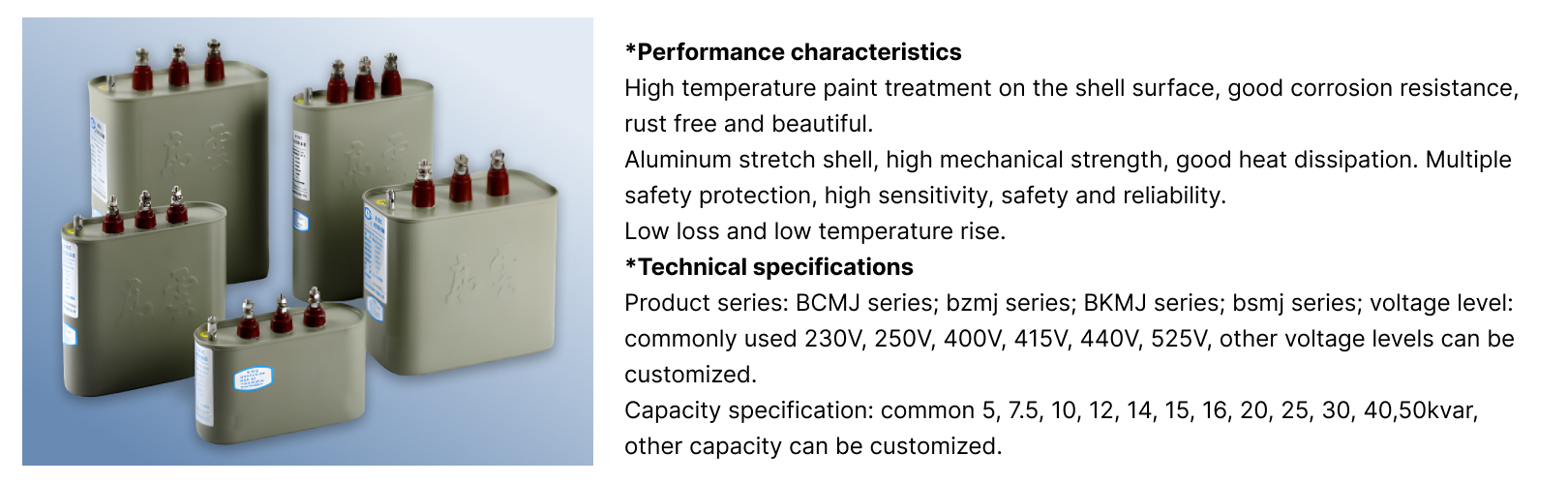

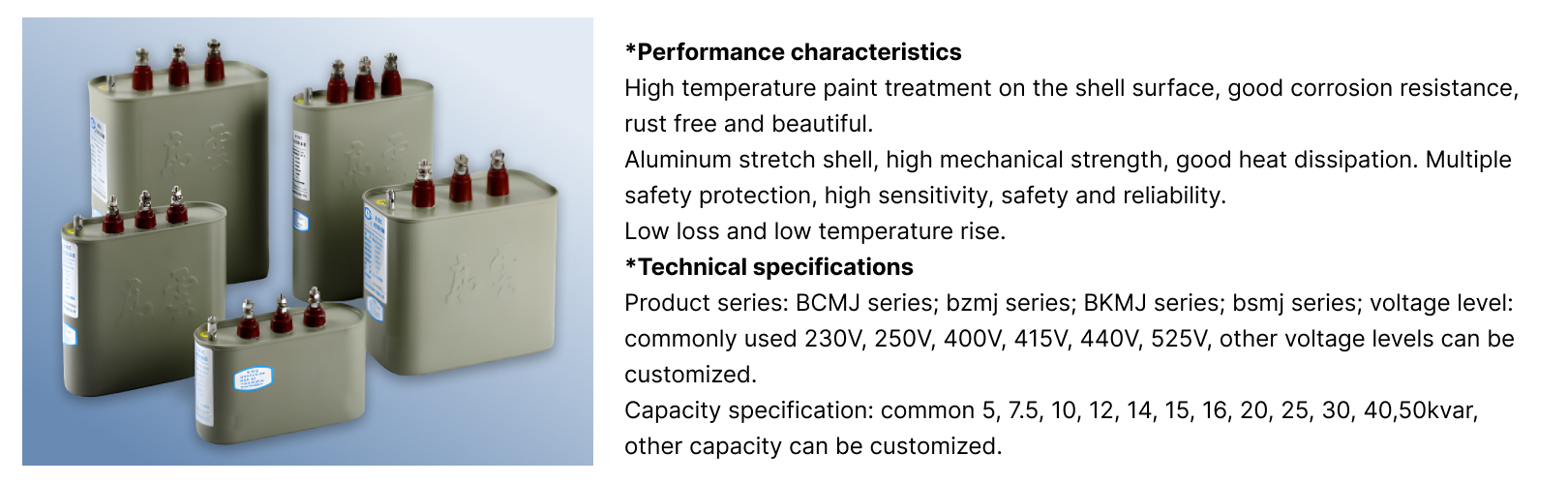

Shell and Surface Treatment

The outer shell is commonly manufactured using an aluminum stretch-forming process. Aluminum provides a balance of mechanical strength, low weight, and thermal conductivity. High-temperature paint treatment applied to the shell surface enhances corrosion resistance, prevents rust formation, and maintains long-term aesthetic and functional integrity in industrial environments.

This surface treatment is particularly important in applications exposed to humidity, dust, or mild chemical atmospheres, such as manufacturing plants or utility rooms.

Dielectric System and Internal Construction

Inside the shell, metallized dielectric films are wound or stacked with precision to achieve the required capacitance and voltage rating. Low-loss dielectric materials are selected to minimize internal heat generation and ensure low temperature rise during operation.

Resin or environmentally compliant filling compounds are often used to stabilize the internal structure, improve insulation, and eliminate leakage risks. These materials also contribute to vibration resistance and long-term reliability.

Electrical Characteristics

Modern cylindrical capacitors are designed for low loss and high thermal stability. Reduced dielectric loss directly translates to lower operating temperatures, which is one of the most critical factors affecting capacitor lifespan. Multiple internal safety mechanisms, such as overpressure disconnection or self-healing metallization, are incorporated to ensure predictable failure modes and system safety.

Key Factors Influencing Quality and Performance

Several engineering and manufacturing factors determine the real-world performance of a cylindrical capacitor:

Thermal Management

Effective heat dissipation depends on shell material, surface finish, and internal layout. Aluminum shells with optimized wall thickness and smooth thermal paths significantly reduce hotspot formation.

Voltage Margin and Dielectric Integrity

Operating a capacitor close to its rated voltage accelerates dielectric aging. Designs that allow stable operation across commonly used voltage levels—such as 230V, 400V, or 440V—provide better reliability in fluctuating grid conditions.

Capacitance Stability

High-quality dielectric films and precise winding processes ensure that capacitance remains within tolerance over time, even under temperature cycling.

Manufacturing Consistency

Automated winding, controlled curing processes, and end-of-line testing reduce unit-to-unit variation, which is essential for multi-capacitor banks.

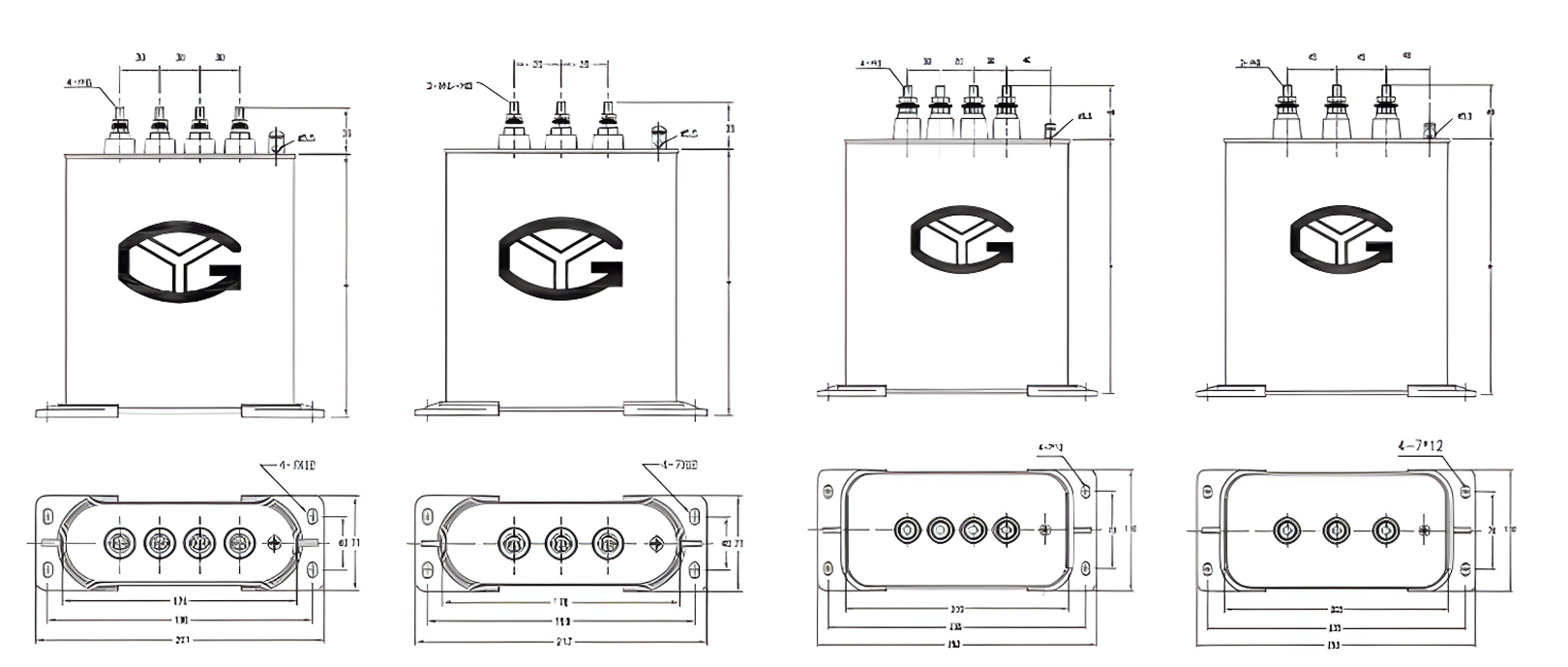

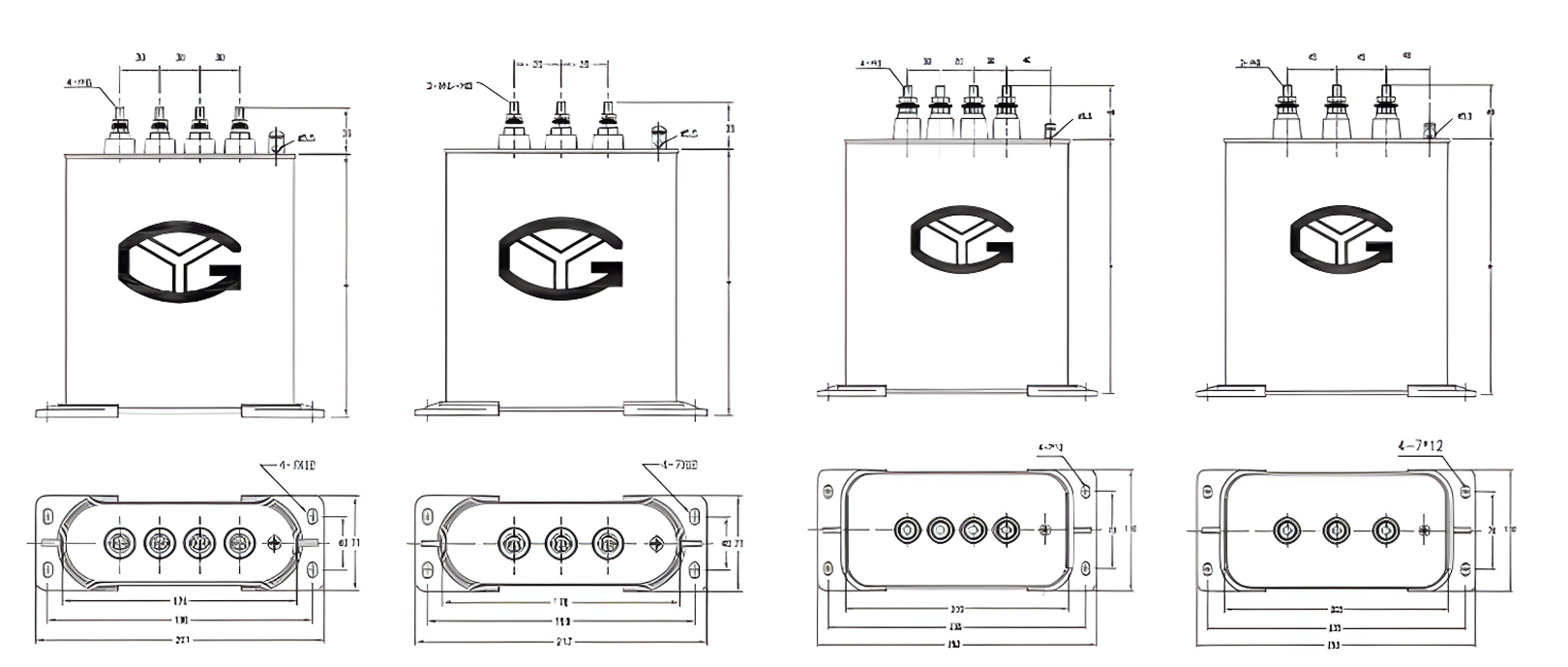

Voltage and Capacity Configurations

Cylindrical capacitors are produced in a wide range of voltage and capacity specifications to match diverse system requirements. Common voltage levels include 230V, 250V, 400V, 415V, 440V, and 525V, allowing integration into both single-phase and three-phase power systems.

Capacitance values typically range from smaller units such as 5 or 7.5 kvar to larger ratings up to 50 kvar. Modular capacity options enable engineers to scale compensation systems incrementally, improving flexibility in design and maintenance. Custom voltage or capacity configurations may be required for specialized equipment or regional grid standards.

Supply Chain and Supplier Selection Considerations

Selecting a cylindrical capacitor supplier is not solely a matter of price. For industrial and infrastructure projects, long-term reliability and technical support are often more critical.

Key evaluation criteria include:

Engineering Documentation and Traceability

Suppliers should provide clear technical specifications, test data, and compliance information.

Process Control and Quality Systems

Consistent production quality is usually supported by standardized manufacturing processes and documented quality management systems.

Application Support

Technical guidance on derating, environmental conditions, and system integration can significantly reduce field failures.

Lifecycle Availability

For long-lived equipment, component continuity and backward compatibility are essential.

Common Industry Challenges and Pain Points

Despite their mature technology, cylindrical capacitors are not immune to misuse or misapplication. Common challenges include premature aging due to thermal overload, incorrect voltage selection, and inadequate ventilation within capacitor banks.

Another frequent issue is underestimating environmental stress factors such as ambient temperature, harmonics, or mechanical vibration. In installations with high harmonic distortion, standard capacitor designs may experience elevated losses, emphasizing the need for proper system analysis during the design phase.

Application Scenarios and Industry Use Cases

Cylindrical capacitors are widely deployed across multiple sectors:

Industrial Motors and Pumps

Used for power factor correction to reduce energy losses and stabilize motor operation.

HVAC and Air Conditioning Systems

Improve efficiency and reduce reactive power demand in commercial buildings.

Elevators and Lifting Equipment

Provide consistent reactive power support during frequent start-stop cycles.

Manufacturing Machinery

Support stable voltage conditions in printing, textile, and automation equipment.

In each of these applications, reliability under continuous operation and compact form factors are decisive advantages.

Trends and Future Development Directions

The future of cylindrical capacitor technology is shaped by higher efficiency requirements, compact system design, and sustainability considerations. Ongoing developments focus on lower-loss dielectric materials, improved thermal modeling, and enhanced safety mechanisms.

Digital monitoring and smart capacitor systems are also emerging, enabling predictive maintenance and real-time performance tracking. As electrical systems become more data-driven, capacitors will increasingly be viewed not as static components, but as integrated elements within intelligent power networks.

Frequently Asked Questions

What distinguishes a cylindrical capacitor from other form factors?

Its geometry supports uniform stress distribution, efficient heat dissipation, and robust mechanical performance.

How does temperature affect capacitor lifespan?

Higher operating temperatures accelerate dielectric aging; low-loss designs with effective heat dissipation significantly extend service life.

Can cylindrical capacitors be customized?

Yes, voltage levels and capacitance values can be adapted to specific system requirements, subject to engineering validation.

Conclusion

Cylindrical capacitors remain a foundational component in modern power systems, valued for their structural reliability, thermal performance, and adaptability across industries. Understanding their design principles, performance drivers, and application contexts enables engineers and system designers to make informed decisions that improve efficiency, reliability, and long-term operational stability.

English

English

Español

Español

Portugues

Portugues

Pусский

Pусский

Français

Français

Deutsch

Deutsch

日本語

日本語

한국어

한국어

العربية

العربية

Italiano

Italiano

Nederlands

Nederlands

Svenska

Svenska

Polski

Polski

Türk dili

Türk dili

हिन्दी

हिन्दी

Indonesia

Indonesia

Melayu

Melayu

dansk

dansk

Magyar

Magyar

বাংলা

বাংলা

עִברִית

עִברִית

čeština

čeština

українська

українська

беларускі

беларускі

Filipino

Filipino

Suomalainen

Suomalainen

اردو

اردو

հայերեն

հայերեն

български

български

Hrvatski

Hrvatski

galego

galego

नेपाल

नेपाल

euskara

euskara

Shqipëria

Shqipëria

Malagasy

Malagasy

Башҡорт

Башҡорт

Türkmenler

Türkmenler

Ilocano

Ilocano

Нохчийн

Нохчийн

Whatsapp

Whatsapp Телефон

Телефон